Brandinfo

Brandinfo

|

What automation means in industrial production?

According to McKinsey, smart technology could boost productivity by up to US$627 billion per year in Southeast Asia. Meanwhile, a survey by Ernst & Young (EY) also emphasised the significance of technology and automation, predicting that by 2035, 45 per cent of supply chains will be largely automated.

Many ASEAN countries have highlighted the importance of technology and digital transformation in manufacturing as a driver of future economic growth. Notably, the Vietnamese Government has set a target for the manufacturing sector to contribute over 30 per cent to GDP by 2030.a

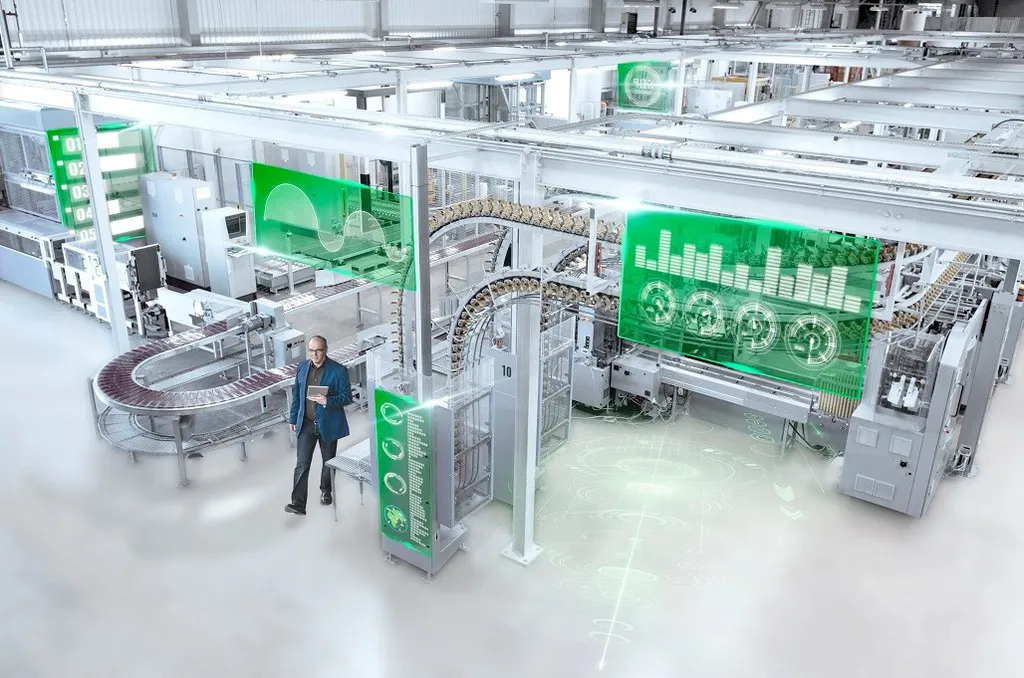

The use of robots and automated control systems offers clear benefits, including optimising performance, reducing process errors, and lowering operating costs. Beyond these advantages, data collected from automated processes is converted into digital form, supporting better business management and analysis. Thus, automation not only streamlines workflows but also opens opportunities to leverage data for strategic decision-making, service improvement, and business growth.

In this context, Schneider Electric believes that adding hardware to the automation segment and advancing AI adoption in industrial automation are essential trends for driving sustainable business growth.

In the Innovation Day Hai Phong, Schneider Electric introduced a wide range of variable speed drives and soft starters offering a powerful and reliable solutions for motor control. As electric motors can account for up to 95 per cent of a plant’s energy consumption, the Altivar Soft Starter serves as a crucial starting point for innovation in any business. Additionally, the newly launched Altivar Process ATV6100 offers an optimal solution for medium voltage drive applications. It helps customers reduce total cost of ownership, streamline processes, and enhance performance. ATV6100 is engineered as a single cabinet system providing custom solutions for a wide range of applications, while eliminating the need for power factor correction in direct-on-line (DOL) operations.

AI adoption optimises industrial automation, promoting scalable sustainable production

In industry, AI can be applied in automation systems, including control devices and production line management, to optimise processes with minimal human intervention. This enhances efficiency, reduces operating costs, and boosts productivity.

At Innovation Day 2025, under the theme Scaling Sustainable Manufacturing through Digitisation and AI, Schneider Electric showcased Industrial Internet of Things (IIoT) technologies powered by Artificial Intelligence (AI). These were integrated across the product lifecycle, including AI-driven automation solutions designed to improve efficiency, security, sustainability, and the cost-effectiveness of manufacturing operations.

Schneider’s Industrial Automation Solutions enhance efficiency, cybersecurity, and sustainability while safely measuring improvements in operational profitability. With innovation integrated at every stage of process control and automation, Schneider Electric accelerates business growth by boosting plant efficiency, increasing reliability and performance, and ensuring operations are safer, more secure, and more sustainable.

As software increasingly defines industrial performance, AI is being embedded into development tools to enable the deployment and management of systems across diverse locations and domains.

|

| Schneider Electric has conducted extensive research to deeply integrate AI with its universal automation solutions, most notably through EcoStruxure Automation Expert |

EcoStruxure Automation Expert, an open automation platform designed to optimise processes and enhance operational efficiency, supports industrial businesses in achieving their goals now and into the future. It simplifies hardware and software integration, accelerates change implementation, and scales flexibly to accommodate new strategies, architectures, and technologies through third-party software integration, ensuring increased operational agility. Additionally, the integration of AI within EcoStruxure Automation Expert brings significant benefits, including predictive maintenance to reduce downtime, process optimization for increased efficiency. These AI-driven capabilities ensure that businesses can achieve higher reliability, performance, and sustainability in their operations.

Importantly, Schneider Electric has introduced CONNECT, an industrial intelligence that enables businesses to unify information and insights in a living digital twin that spans design, operational performance, energy management and carbon efficiency. CONNECT uses artificial intelligence to synthesize thousands of perspectives into one shared reality, one unified experience. CONNECT addresses a critical challenge facing Vietnamese manufacturing businesses: the prevalence of disparate software platforms, poor system interoperability, and the underutilisation of data. Currently, around 73 per cent of data collected from internal operations is unused, and 76 per cent of business leaders report difficulty understanding their data.

|

Moreover, CONNECT provides access to a wealth of information from across the industrial ecosystem accelerating the network effect by leveraging the latest advanced in analytics and AI, and quickly integrating applications from multiple vendors including AVEVA, Schneider Electric, RIB, ETAP and other CONNECT ecosystem partners.

Especially, AVEVA's predictive analytics tools can be integrated with CONNECT to monitor asset health, forecast remaining asset life, and reduce unplanned downtime. AI-driven process optimization solutions from AVEVA can utilize CONNECT's data integration capabilities to improve yield and operational efficiency. Advanced pattern recognition and machine learning algorithms from AVEVA can be deployed on CONNECT to identify anomalies in processes and equipment. Additionally, CONNECT can leverage AVEVA's prescriptive guidance and risk-based decision support tools to enable smarter decision-making and minimize risks.

Schneider Electric is committed to supporting industrial businesses in Hải Phòng City and across Việt Nam in adopting and mastering digital and AI technologies. Through this, the country can scale up production, enhance competitiveness within global supply chains, and realise its net-zero ambitions.

.jpg)