Brandinfo

Brandinfo

Eurorack Wifi Shuttle | The Smart Warehousing Solution for the Industry 4.0 Era

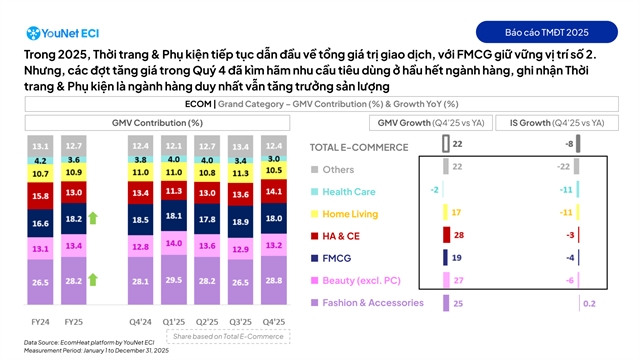

In today’s supply chain landscape, logistics is considered the “lifeblood” of business operations. Warehouse optimisation is no longer just about efficient management, but a decisive factor in building competitiveness. Traditional storage models have shown multiple limitations, such as space wastage, high labour costs, and operational risks. Now, automation technology is opening a new chapter.

|

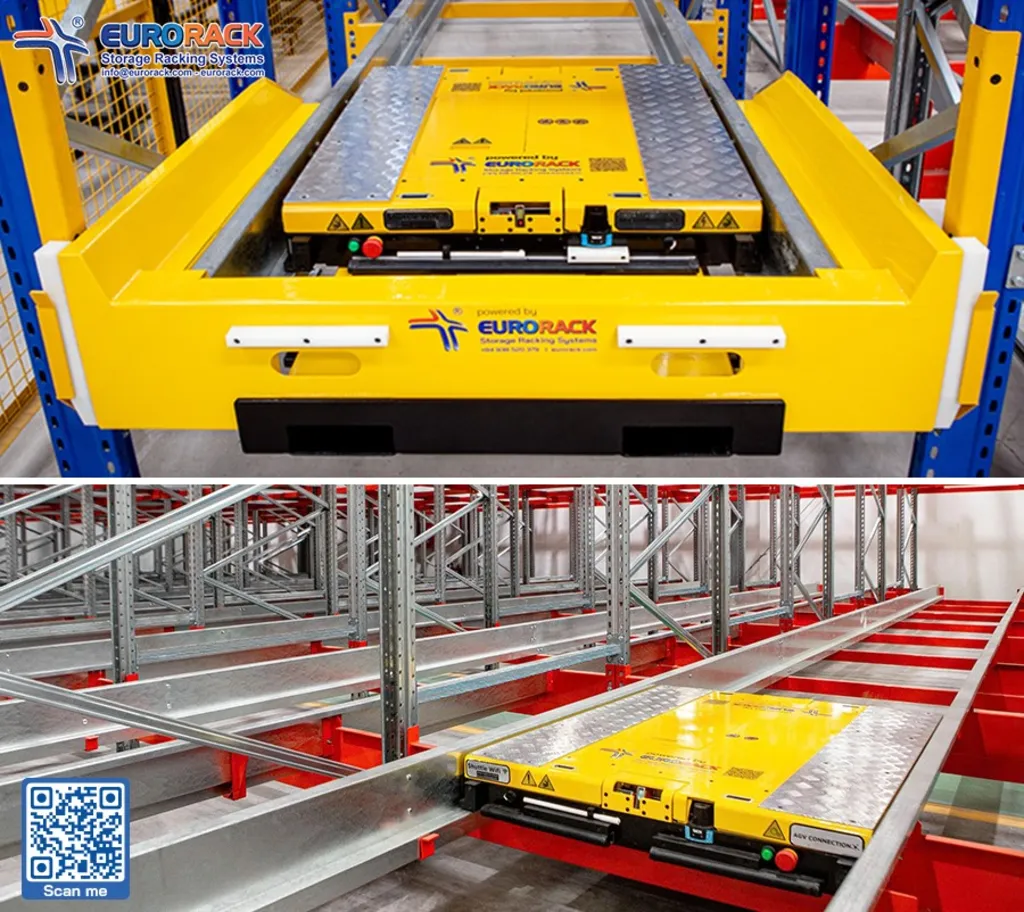

| Eurorack Wifi Shuttle – A Smart Robotic Racking System that Maximises Storage Capacity |

Recognising this trend, Eurorack, backed by over 15 years of expertise in warehousing solutions, has introduced the Eurorack Wifi Shuttle Robot (Previous version of Robot Eurorack Radio Shuttle), a next-generation automated racking system (Automated Warehouse, Smart Warehouse, Eurorack Orbiter). By integrating intelligent robotics, this solution represents a significant leap in Việt Nam’s smart warehouse movement, enabling businesses to cut costs, maximise space, and enhance operational safety.

Intelligent Operation Technology with Robot Shuttle

Also known as the Eurorack Orbiter, the system combines high-density racking with rail-guided robotic shuttles. Controlled remotely via WiFi, the shuttle can operate continuously for more than 10 hours using lithium batteries. With a load capacity of over 1,500 kg per pallet, it adapts to diverse storage needs, including ambient and cold storage environments from –30°C to +55°C.

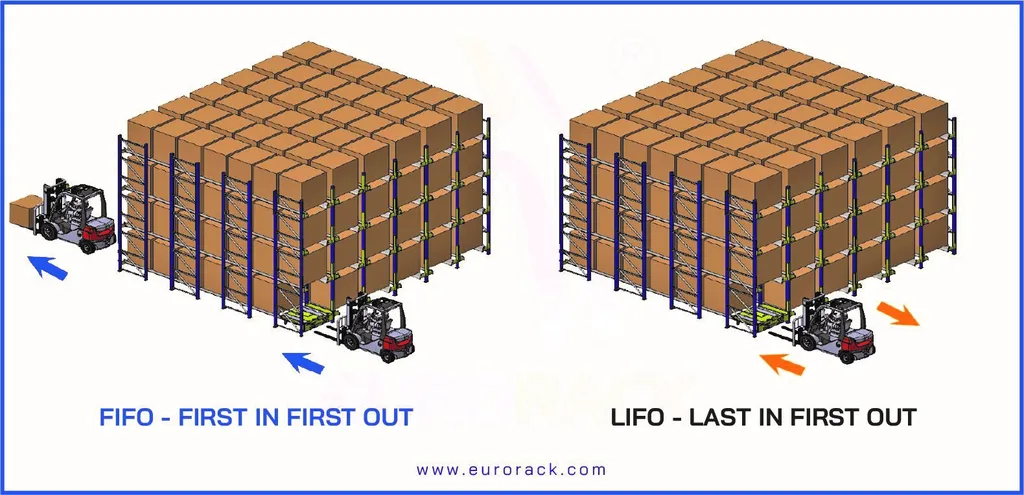

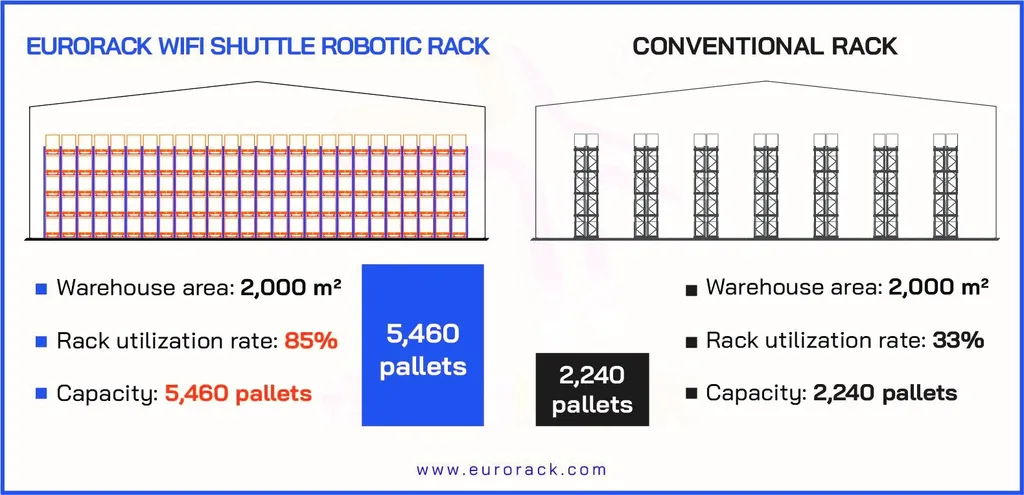

Unlike conventional forklifts, which must enter deep aisles, the shuttle ensures that forklifts stay at the rack entry point, minimising collision risks while increasing storage density by up to 2.4 times compared to traditional racking, all with lower capital investment. The system offers two flexible modes:

● FIFO (First In, First Out): Ideal for perishable goods requiring fast turnover.

● LIFO (Last In, First Out): Optimises rack depth while minimising travel distance.

|

| Illustration of the operating principle of the Eurorack Wi-Fi Shuttle robotic rack |

Key Advantages of the Eurorack Wifi Shuttle

● Maximised Storage Utilisation: With only a single aisle required for operation, storage capacity can increase by more than 2.4 times, without expanding the warehouse. This is especially valuable as land and rental costs continue to rise.

|

| Within the same 2,000 m² area, the Eurorack Wi-Fi Shuttle robotic rack increases storage capacity by more than 2.4 times compared to conventional racks (from 2,240 to 5,460 pallets). |

● Reduced Operating Costs: By minimising the need for forklifts and manual labour, businesses can significantly cut management expenses. In cold storage environments in particular, optimising storage space and shortening goods transfer time enable faster cooling, minimise heat loss, and substantially reduce the energy consumption of refrigeration systems.

● Accurate Inventory Control: Combining FIFO/LIFO with warehouse management software (WMS) ensures seamless expiry-date control, traceability, and error-free stocktaking.

● Enhanced Workplace Safety: Forklifts no longer need to enter deep aisles, and staff avoid working in confined spaces, reducing accidents and creating a safer, more professional working environment.

|

| Eurorack Wi-Fi Shuttle Robotic Rack – Maximising Warehouse Storage Capacity |

Eurorack – A Leading Manufacturer of Racking & Logistics Solutions

Eurorack operates a modern factory equipped with ISO 9001:2015-certified production lines, guaranteeing both speed and quality. Over the past 15 years, the company has completed thousands of projects nationwide, becoming a trusted partner of CJ Food, Ajinomoto, Nestlé, and many other global brands.

|

| Automated storage and more than double the capacity without expanding floor space |

Beyond racking systems, Eurorack provides end-to-end logistics solutions: from design, manufacturing, and installation to strategic consultancy. Its proven track record across multiple industries demonstrates its capability and reliability.

In the Industry 4.0 era, warehouse storage optimisation is not just about cost reduction; it is a key driver of business leadership. The Eurorack Wifi Shuttle (Eurorack Orbiter) is a hallmark of Việt Nam’s technological advancement in logistics, affirming Eurorack’s growing position in the global market./.

Eurorack JSC – Mechanical Engineering

● Hotline: (+84) 938 520 379

● Email: info@eurorack.com

● Website: www.eurorack.com

● Head Office: 5/3 Đoàn Thị Điểm, Cầu Kiệu Ward, Hồ Chí Minh City, Việt Nam

● Office: 3323 183rd Street, Homewood, Illinois 60430, USA

● Showroom: The Olympia Mall, Phnom Penh, Cambodia

● Factory: 220 Trịnh Thị Miếng, Đông Thạnh, Hồ Chí Minh City, Việt Nam