|

| A view of the Concentrated Information Technology (IT) Zone of Đà Nẵng Software Park 2. — VNA/VNS Photo Văn Dũng |

ĐÀ NẴNG — As the central city of Đà Nẵng aims to be one of Việt Nam’s three leading semiconductor and microchip hubs by 2030, home to a high-quality manpower training network linked with a comprehensive semiconductor ecosystem, concerted efforts are being made to realise that goal.

The target is in line with the national semiconductor industry development strategy until 2030, with a vision to 2050.

Investment in semiconductor packaging, testing infrastructure

The VSAP LAB Joint Stock Company recently started work on a laboratory for the production of advanced packaging technologies (fab-lab) at the Concentrated Information Technology (IT) Zone of Đà Nẵng Software Park 2.

This project, a pioneering model in Việt Nam, plays a strategic role in advancing core technologies, in accordance with the Politburo's Resolution No. 57-NQ/TW and the national semiconductor industry development strategy by 2030, with a vision to 2050. It is also a strategic step in Đà Nẵng's semiconductor and artificial intelligence development plan.

With a total investment of VNĐ1.8 trillion (US$68.8 million) and spanning 2,288 sq.m., the fab-lab project is set to begin operations in the fourth quarter of 2026. It will have a designed capacity of 10 million products annually, catering to both domestic and international markets.

According to Nguyễn Bảo Anh, CEO of the VSAP LAB JSC, the global semiconductor industry is shifting strongly but there remain bottlenecks related to the supply – demand balance. Those bottlenecks do not lie in the stages of chip design or manufacturing but in advanced packaging – a key step determining the efficiency, size, reliability, and production cost of semiconductors.

This fab-lab will be the first facility in Việt Nam capable of developing and producing advanced packaging technologies on a trial basis such as RDL Fan-out, 2.5D, and 3D packaging—fundamental for AI chips, high-performance data centre chips, automotive chips, and next-generation electronic devices.

The fab-lab model being developed in Đà Nẵng represents a flexible public-private partnership, becoming the first in Việt Nam to fully integrate research, production, testing, human resources training, and technology transfer in the field of advanced semiconductor packaging technologies.

Lương Nguyễn Minh Triết, Chairman of the Đà Nẵng People’s Committee, said science – technology development, innovation, and digital transformation were identified as the city’s top priority for 2025–2030.

As VSAP LAB was expected to become an exemplary fab-lab model, municipal authorities pledged to provide favourable infrastructure, administrative, and manpower conditions for the project to be carried out on schedule, safely, and efficiently, he noted.

VSAP LAB would serve as the core for developing a semiconductor innovation cluster, helping realise Đà Nẵng's ambition to become a national high-tech hub, he added.

Human resources development, talent attraction

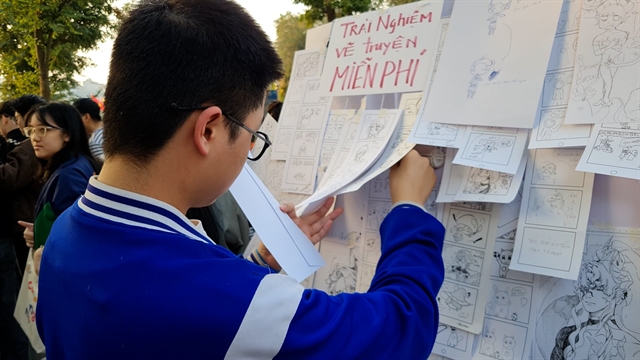

|

| Semiconductor and AI startups are supported with workspace at the Concentrated Information Technology (IT) Zone of Da Nang Software Park 2. — VNA/VNS Photo Mỹ Hà |

Đà Nẵng aims for its digital economy, by 2030, to make up at least 35–40 per cent of the total GRDP and attract a minimum of 5,000 high-quality semiconductor professionals, including 1,500 design engineers and 3,500 testing and packaging ones. The force will not only meet local demand but also serve other Vietnamese localities and some international markets having partnerships with this city.

To train and supply a skilled semiconductor workforce, universities in Đà Nẵng are focusing on training in chip design, testing, physical design, and chip architecture design, while strengthening cooperation with global semiconductor organisations and businesses. The National Innovation Centre will also develop a shared database to support training across the universities offering semiconductor programmes.

In addition, the city is offering several incentives to learners and experts. Many outstanding policies with total funding of about VNĐ873 billion ($33.2 million) have been issued, including benefits, income, and accommodation for professionals and scientists directly involved in research, training, and connection of semiconductor development programmes.

Phil Hoàng, a semiconductor expert at the US-based technology expert organisation TreSemi, perceives that Đà Nẵng has taken right steps to prepare human resources for the semiconductor industry. It has launched concrete projects that gather State agencies, businesses, universities, experts, and potential partners to set up training orientations and manufacture globally competitive chips.

He underlined TreSemi’s support for Đà Nẵng to hold in-depth training courses to create top-tier engineers.

Developing high-quality human resources to meet businesses’ demand is also believed to generate an opportunity for the city to have sufficient international-standard manpower to welcome a new investment wave.

Currently, Đà Nẵng hosts around 10 active semiconductor design companies, including Synopsys, Uniquify, Savarti, Renesas, Synapse, FPT Semiconductor, and Viettel CNC, employing roughly 550 engineers. — VNS