Society

Society

|

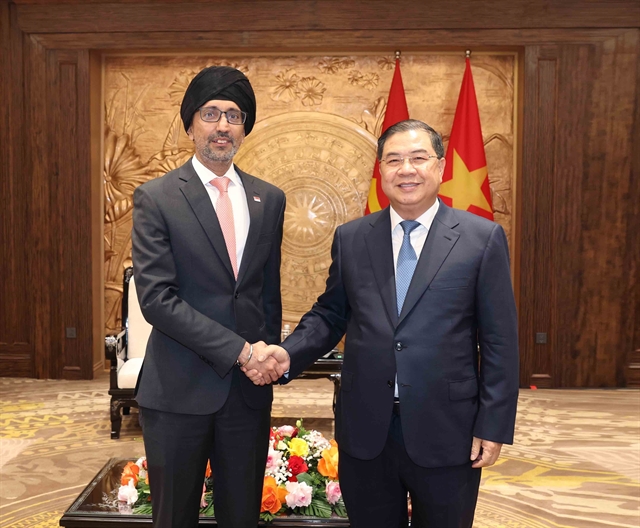

| Phạm Minh Long Hải (sitting), Bùi Nguyễn Khánh Linh, Nguyễn Xuân Bảo and Nguyễn Minh Anh (from left to right) receive the first prize in the Kawai Start-up Competition 2023. — Photos courtesy of Long Hải |

Thu Trang

HÀ NỘI — Despite their young age and modest experience, a group of four students in Hà Nội have successfully produced biomass blocks from coffee grounds for use as an environmentally friendly fuel.

The biomass blocks are assessed to have many outstanding advantages compared to gas, firewood and coal.

The outstanding group includes Phạm Minh Long Hải and Nguyễn Xuân Bảo, from the Hà Nội University of Science and Technology; and Bùi Nguyễn Khánh Linh and Nguyễn Minh Anh, from the Hà Nội Foreign Trade University.

The project “Coffuel - Innovative solution in recycling industrial by-products to create a sustainable energy supply” recently won first prize in the Start-up Competition 2023 – the first of its kind organised by the Hà Nội Youth Union.

The project impressed people because the blocks made from discarded coffee grounds are changed into fuel.

The fuel can be used for industrial boilers, heating, cooking food, and outdoor activities such as picnics and camping.

Project founder Phạm Minh Long Hải told Việt Nam News that the blocks could burn for a long time with remarkable productivity.

Hải, a third year student in food engineering, added that the heat generated from the coffee grounds biomass blocks was 120 per cent stronger compared to traditional wood pellets.

“They reduce carbon dioxide emissions into the environment by up to 90 per cent compared to coal and reduce the amount of ash remaining after burning by 85 per cent compared to other traditional fuels,” said Hải.

“In particular, biomass blocks from coffee grounds can be designed based on customer requirements, increasing the users’ enjoyable experience,” he said.

Idea

Hải said that many times when he went out to drink coffee, he witnessed coffee grounds being thrown away after brewing, which was very wasteful, while Việt Nam was one of the countries with the largest coffee consumption in the world.

“Applying my specialised knowledge at university, I developed a plan to utilise coffee grounds to make useful products for the people,” he said.

Hải shared the idea with his friend Nguyễn Xuân Bảo, who is studying Chemistry and Life Science at the Hà Nội University of Science and Technology.

He received agreement and encouragement from Bảo.

Bảo said, “I have a lot of sympathy with Hải because once I went to the Central Highlands province of Đắk Lắk with my friends, I saw local farmers working very hard to make coffee. The path from the coffee beans to a cup of delicious café is too long, but after that, too little value is retained.”

And so, the Coffuel project was kicked off.

“We believe that one day, we will live our lives with greener energy, and when farmers put so much effort into growing and harvesting coffee beans, they will know that none of their efforts are left behind,” said Bảo.

Hải and his team determined to turn their ideas into reality.

They started their research in 2022.

“At first, we intended to make shirts and cups from coffee grounds. However, after many experiments, we realised that the effort and cost were too high. We decided to make burning fuel blocks to replace coal, wood and gas from the grounds," said Hải.

“We studied documents from professors and experts at the Tokyo University in Japan. But we encountered many problems, from production techniques to funding and workshop shortage," said Hải.

Bùi Nguyễn Khánh Linh, a member of the team, told Việt Nam News that to solve the problems, the team had to try numerous ways.

“We used our own money, borrowed the university's laboratory for research, and borrowed a workshop from our acquaintances to produce the blocks,” said Linh.

During the project process, the team had many controversies, the biggest being about what the next stage should be.

“We are students and do not have much capital, so we have to consider very carefully what to do next, because if we miscalculate or do something wrong, we will not have funds to continue,” said Linh.

Talking about difficulties that the team faced in the early days, Bảo added that there were really too many to summarise in a few sentences.

“We worked 12-16 or even 20 hours a day, seven days a week. I find that there is no real magical path for success other than we must have the will, we dare to do and dare to try everything. We must have endurance and perseverance to achieve the set goal at all costs,” said Bảo.

In the end, the team found a common voice and worked side by side to reach success.

Joy

|

| The team’s products. |

After more than a year of research and experiment, the first biomass blocks from coffee grounds were made, to the joy of the team.

The team collect residue from coffee processing plants and sawdust from furniture workshops.

Coffee grounds are treated for odour, removing excess essential oils and particles that do not meet size standards.

Sawdust is screened for desired size, cleanliness and moisture.

The raw materials are put into an industrial drying system to bring the moisture to about eight to 10 per cent.

After the drying stage, the team mixes the materials with the rate of 50-55 per cent coffee grounds, 42-44 per cent sawdust, and heat to keep the mixture at the right moisture level, avoiding mould.

The temperature is maintained at 75-80 degrees Celsius to form a natural adhesive.

In the final step, the material will go through a high-pressure pressing process and be pressed into blocks.

However, they once again met failure.

After only one week the blocks broke down into a powder like their initial form.

Not discouraged, the four young people continued efforts for further research and constantly improved their techniques.

“Finally, the sweet result has come with us. Our product now can be stored for four or five months,” said Hải.

The team then thought about the next stage, bringing the product into the market.

They introduced and advertised their product through many channels such as acquaintances, factories and forums.

The first three boxes of biomass blocks were sold last April.

“We are very happy because our product has been trusted. That gave us more motivation to move forward," said Hải.

Then, the team received different orders from many customers.

“In the future, we will develop our products to export to foreign markets,” said Hải.

They also completed procedures for registering intellectual property rights.

The Coffuel project won many awards such as the first prize in the Kawai Start-up Competition 2023, the first prize in the Hust – Techstart Competition for Students 2023, the first prize in the Start-up Competition 2023 and the second prize in the "Young Start-up" Competition 2023. — VNS