Economy

Economy

|

| THACO INDUSTRIES pays close attention to research and mastering mould manufacturing technology. — Photo courtesy of THACO INDUSTRIES |

HCM CITY — As a large-scale manufacturer in the mechanical engineering and supporting industries in Việt Nam, THACO INDUSTRIES has focused on investing in mould manufacturing to make a variety of them for various industries.

Mould manufacturing technology plays an extremely important role in manufacturing and is considered the foundation of modern manufacturing by enabling mass production in a short time and with high precision.

However, to meet the requirements for autonomy in mould manufacturing technology, Vietnamese firms need to invest more in technology, expanding production scale and improving human resource.

Mastering mould manufacturing technology

In 2016 THACO INDUSTRIES put into operation a mould plant to serve its large-scale production activities and meet the market’s needs.

In 2022 it invested US$36 million to expand the plant’s area to 4,400sq.m and annual capacity to 1,000 sets of moulds and 2,000 tonnes of precision mechanical components.

Mould manufacturing is a highly automated industry, requiring complex techniques and high precision, and so THACO INDUSTRIES pays special attention to research and mastering technology.

It has invested simultaneously in all mould production processes such as preform mould design, deep hole drilling, CNC milling, EDM machining, wire cutting machining, CMM measuring, and mould assembly using modern equipment and machinery such as 5-axis milling machines from Japan, the first of its kind in Việt Nam, press machines with a maximum pressure of up to 200 tonnes, and double head EDM machines that can work on one or two different moulds.

The machining process in CNC (Computer Numerical Control) machines is fully automated with digital control, ensuring accuracy, aesthetics and saving manpower and time.

|

| Mould machining with a 5-axis milling machine. — Photo courtesy of THACO INDUSTRIES |

THACO INDUSTRIES produces various products, including plastic moulds, stamping moulds, blow moulds, extrusion moulds, and SMC moulds used in several sectors such as automotive, industrial, agriculture, and civil.

It boasts high capabilities in making medium and large-sized plastic moulds as currently most mould manufacturing companies in Việt Nam produce mainly small-sized moulds due to their limited production scale, technology and equipment.

|

| Mould products of THACO INDUSTRIES. — Photo courtesy of THACO INDUSTRIES |

There is an increase in demand for moulds in car and motorbike manufacturing, refrigeration and others. With its outstanding production capacity, a team of highly qualified experts and engineers trained in South Korea and modern simulation and calculation software (NX, Mouldow, Hyperform...), THACO INDUSTRIES can design and develop products swiftly and meet technological parameters and the stringent requirements of customers.

The company has produced large, complex moulds with high aesthetic features for the automotive industry such as 27-tonne truck bumper moulds, passenger car rear bumper moulds using Hiddenline technology, luggage compartment moulds and moulds for passenger car interior components using 3D corrosion technology, moulds for making details of passenger car sunroof frames.

|

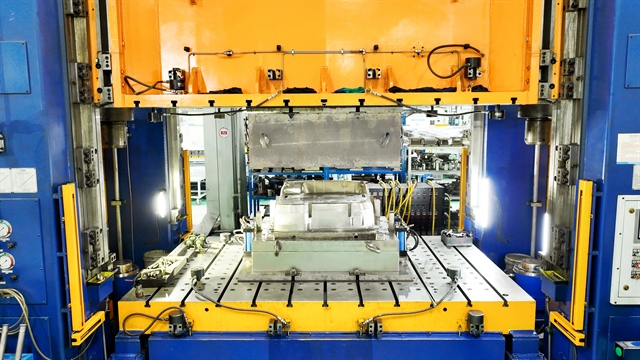

| A 1,000-tonne hydraulic SMC moulding press machine at THACO INDUSTRIES’s Mechanical Complex. — Photo courtesy of THACO INDUSTRIES |

THACO INDUSTRIES is a reputed mould manufacturing and supply partner for many brands such as Mazda, Kia, QCM, Doosan, Makitech, Hữu Toàn, THACO BUS, and LIXIL in the domestic market. It also exports many products to the US, Canada and South Korea.

Affirming role in supply chain

THACO INDUSTRIES promotes R&D and learns new mould manufacturing techniques to help increase the rate of use of local parts in the automotive industry and improve the competitiveness of the country’s mould manufacturing industry.

The company is researching and analysing the simulation of flow in plastic moulds and plastic deformation of metals in large plate stamping moulds to produce passenger car bumpers and automobile body moulds.

These are large, complex moulds and are of high commercial value. At the same time the production of these moulds will boost mould manufacturing development for the automotive industry.

THACO INDUSTRIES is also developing products like aluminium pressure die casting moulds, PU foam moulds and heat press moulds to supply to domestic customers and export to the US, Europe, and South Korea.

Mastering mould manufacturing technology helps THACO INDUSTRIES be proactive in production and business, completing the value chain in accordance with the “All-in-one” model (providing complete solutions from product research and development to processing and manufacturing, assembly and transfer of operation and maintenance) and highly competitive when participating in the global supply chain.