Economy

Economy

Nguyễn Phương, sales director of Minh Thành Co., Ltd, said his company plans to invest more than VNĐ50 billion (US$2.15 million) in a production chain for bedroom and living room furniture.

|

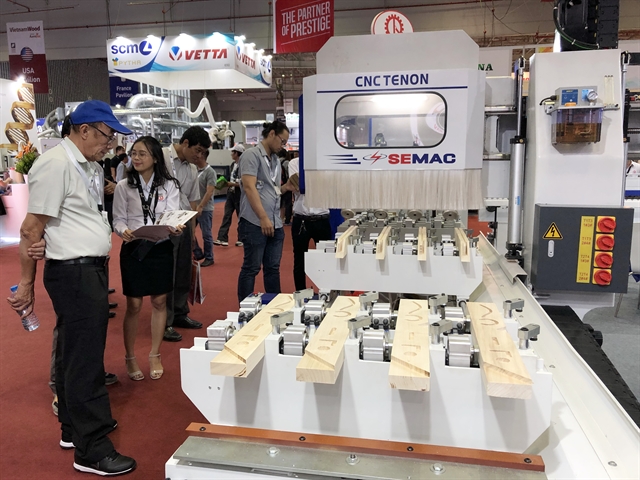

| Machinery on display at the recent International Woodworking Industry Fair held in HCM City. Woodworking firms are increasingly investing in advanced technologies to improve their competitiveness. — VNS Photo |

HCM CITY — Nguyễn Phương, sales director of Minh Thành Co., Ltd, said his company plans to invest more than VNĐ50 billion (US$2.15 million) in a production chain for bedroom and living room furniture.

Besides installing a new machine, the company has also revamped its production process to create the most compatible and efficient machine system, he said.

With this, Minh Thành expects to reduce manpower by around 30 per cent and improve productivity and quality.

Leslie Lye, sales manager at the Weinig Group, said: “Vietnamese producers have been making more investment in technology than in other Southeast Asian countries.”

But with customer preference shifting to personalised furniture, the production costs of such customised furniture must be comparable with that of mass produced items, he said.

This is affecting furniture manufacturers globally and in Việt Nam.

He said furniture manufacturers need to have factories with mass production capacity but also the flexibility to make small batches.

“To be profitable, they need to have a precise mapping of the production process and easy and quick product changeover.”

Nguyễn Chánh Phương, deputy chairman of the Handicrafts and Wood Industry Association of HCM City (HAWA), said the high growth rates in recent years notwithstanding, the wood processing industry faces challenges like fierce competition due to an increasing number of foreign enterprises investing in the sector but also a shortage of workers as a result, and a shifting of orders from China.

Firms in industrial parks pay 10-20 per cent higher wages than previously, but still find it hard to get workers, he said, adding that despite rising wages, labour productivity remains low.

The country’s wood and forestry exports were worth over US$7.9 billion in the first nine months of the year, a year-on-year increase of 18.1 per cent.

Nguyễn Quốc Khanh, HAWA chairman, said: “All enterprises in the industry are heading towards a bigger goal of $20 billion in 2025.

“The Government has set a clear direction of making Việt Nam a world leading woodworking production centre. This has helped companies in the sector gain confidence and motivation.”

To cope with current and prospective challenges and changes in customers’ demands, the industry needs to adopt effective business strategies and embrace advanced technologies, he said.

“With the progress in global machinery manufacturing, our woodworking companies are able to get the latest technologies, especially precision production technologies by using computer numerical control (CNC).

“Current emerging technologies such as AI, big data, cloud computing and robotics will surely enable us to improve product quality, better control the production process, reduce dependency on manpower and the time taken for production, and quickly meet customer demands.”

When investing in technologies, firms should base it on future needs and seek advice from experts and machinery suppliers, he added.

Bernd Kahnert, senior expert at HOMAG, the world’s leading supplier of smart and integrated production solutions for the wood industry, said finding human resources who can understand and operate these advanced technologies would not be an easy task for Vietnamese firms.

Enterprises themselves can resolve the human resource challenges but it needs closer collaboration between educational institutions and businesses, he said.

Training human resources for the industry is an urgent requirement, he added. — VNS