Brandinfo

Brandinfo

Coconut beverages and foods, such as fresh coconut water, coconut milk, and coconut cream, have become deeply entrenched in the daily consumption habits of people worldwide over the past few years. Consumers favour coconut products for their low cholesterol and calorie content, along with essential vitamins, minerals, and amino acids. According to data from the Vietnam Coconut Association, eight of the top ten countries for coconut production are in the Asia Pacific, with Vietnam ranking fourth in terms of export value.

However, coconuts are considered among the hardest raw materials to work with. Coconut water is a perishable food that quickly loses its nutrients and flavour due to natural enzymatic activity as soon as the fruit is opened. Therefore, coconut water and its components must be processed quickly to minimise food waste.

Backed by over 70 years of expertise in global food processing and packaging, and more than 30 years of partnership with the coconut industry, Tetra Pak has introduced Direct UHT technology and innovative packaging solutions to enable maximum taste and nutrition control to secure the quality of end products. At Coconext 2024, Vietnam's first international conference on coconuts, the company showcased advanced, modern processing and packaging solutions for the industry. These innovations aim to help Vietnamese businesses expand their product portfolios, enhance product values, and boost competitiveness in the global market.

Tetra Pak’s Direct UHT Technology: A revolutionary solution for coconut processing

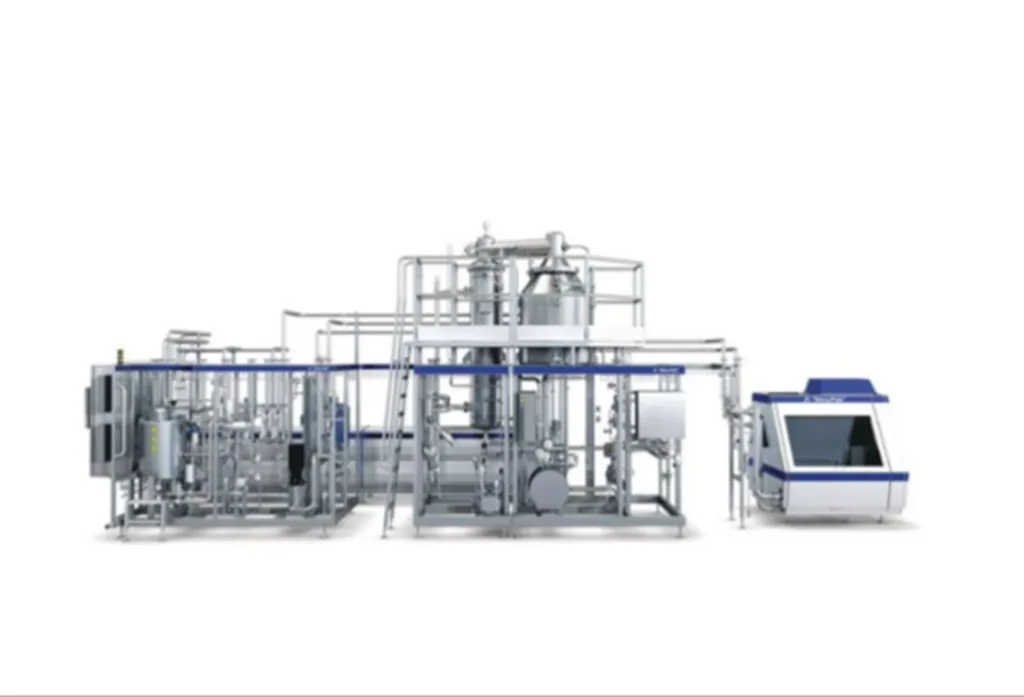

Tetra Pak introduces a groundbreaking advancement in food processing with its Direct Ultra-High Temperature (UHT) technology. This state-of-the-art method employs ultra-high heat for an extremely short duration to effectively eliminate harmful microorganisms, followed by rapid cooling. The innovative approach ensures that the natural flavour and nutritional integrity of coconut products are preserved while extending their shelf life to up to 12 months—eliminating the need for preservatives or refrigeration.

|

| Tetra Pak’s Direct UHT Technology preserves the freshness and nutrition of coconuts. |

Key advantages of Tetra Pak’s Direct UHT units include:

• Easily customised to meet your application needs: This technology is adaptable for various coconut products, especially coconut water and coconut milk, meeting the long-term production needs of businesses.

• Preserve the quality of your oroducts: Through rapid heating and cooling processes, the technology ensures the retention of essential nutrients and the natural flavour of fresh coconuts, delivering high-quality products to consumers.

• Take efficiency to a new level: The direct UHT system is designed to save energy, minimise by-products, and support businesses in achieving their sustainability goals.

• End-to-end line expertise from one partner: The technology seamlessly integrates with modern monitoring systems, enabling businesses to fully control production processes and enhance the quality of their output.

Tetra PlantMaster - Paving the way for lower TCO, higher efficiency, and greater profitability

At Coconext 2024, experts emphasised that adopting advanced technology is no longer an option but a necessity for the industry's sustainable development and enhancing supply chain value. Nguyễn Thị Kim Thanh, President of the Vietnam Coconut Association, underscored the importance of building a comprehensive, modern, and sustainable value chain for the coconut sector. She highlighted the need for enterprises to invest in advanced processing facilities, adopt high-tech production methods, and focus on organic practices to boost productivity and product quality.

As the world’s leading player in food processing and packaging, Tetra Pak introduced Tetra PlantMaster, a plant automation solution specifically designed for food production. It covers your entire operation from raw material intake to packaged and palletised products. Although complex on the inside, it explains everything through one comprehensible, intuitive interface.

This solution enables businesses to optimise production costs, enhance competitiveness, and ensure efficiency at every stage of the production process - from raw material preparation to product packaging. With these cutting-edge solutions, Tetra Pak reaffirms its leadership in supporting the food processing industry to achieve sustainable development goals.

|

| Tetra Pak Representative Showcases Advanced Processing Solutions for the Coconut Industry |

Ngo Thanh, Processing Director at Tetra Pak Vietnam, said: “Through our collaboration with customers, Tetra Pak is committed to delivering advanced and sustainable processing and packaging solutions that enhance the value of coconut products.

"Furthermore, we support our clients in optimising operational costs, ensuring consistent product quality, and enabling seamless product traceability. These efforts bolster the credibility and competitive edge of businesses in the market.”

In support of Vietnamese food and beverage (F&B) businesses in adapting to the evolving market, Tetra Pak is committed to providing world-class advanced technologies and solutions to help customers expand their product portfolios and achieve specific sustainability goals.

One example is the Bloom Centre in Binh Duong, which assists businesses in developing coconut-based products that meet consumers’ diverse needs. Tetra Prisma Aseptic packaging offers a convenient and fresh coconut water experience, while Tetra Recart expands the range of shelf-stable ready-to-eat meals without preservatives.

With a comprehensive range of creative and sustainable solutions, Tetra Pak is helping businesses maximise the value of coconuts, creating products that align with trends and cater to increasingly diverse consumer demands.

Discover more about these solutions here.