Brandinfo

Brandinfo

Shaping the future of the kitchen cabinets where sustainability meets performance

As global demand for sustainable furniture continues to rise, Việt Nam's manufacturing sector is positioning itself as a key player in the international supply chain, especially in the production of kitchen cabinets.

|

| Kitchen cabinet manufacturing is becoming a key segment within the global furniture supply chain. |

This transformation is being fueled by strong foreign direct investment (FDI), driven by the country's cost competitiveness, skilled labour force and increasing alignment with global environmental standards.

Despite the complex fluctuations of the world market, Việt Nam's wood and wood products export industry is recording positive signs of recovery.

Among key segments, kitchen cabinet manufacturing stands out as a significant contributor to Việt Nam’s export revenue.

According to the Ministry of Agriculture and Environment, the total export turnover of wood and wood products in the first five months of 2025 reached about $6.99 billion, an increase of 11.5 per cent over the same period last year.

However, this high-value sector is now facing a convergence of challenges. As global markets implement more stringent environmental and product safety standards, manufacturers must meet expectations not only for design and durability but also for compliance with evolving regulations.

Among those are Kitchen Cabinet Manufacturers Association (KCMA), a US certification, requiring high standards for emissions and durability, the Leadership in Energy and Environmental Design (LEED) certification, encouraging sustainable materials and low-emission finishes and Volatile Organic Compounds (VOC) emission limits, which directly impact worker safety, indoor air quality and export eligibility.

Kitchen cabinets are no longer just an aesthetic concern. In today's global market, it is a critical touchpoint that defines the functionality, compliance, and environmental footprint of a product.

This regulatory tightening comes at a time of increasing operational costs, shifting trade policies, and rising consumer scrutiny, all of which are pushing cabinet manufacturers to rethink every element of their production process, particularly the finishing phase, where the choice of coating technology can determine both product competitiveness and market access.

For export-oriented OEMs, especially the FDI companies, selecting the right coating solution is not merely a matter of product quality, it is a strategic decision that affects everything from cost structure and operational sustainability to global market positioning.

As Việt Nam transitions toward a more sustainable and innovation-driven manufacturing model, forward-thinking suppliers of coatings and finishing technologies are stepping up to support the shift.

These partners are not only delivering advanced materials but also enabling furniture and cabinet makers to future-proof their businesses, respond to ESG commitments, and contribute to a low-carbon economy.

Manufacturers that embrace next-generation industrial wood coatings, those that combine sustainability, high performance and regulatory readiness, will be better positioned to thrive in global markets where green credentials are becoming a requirement rather than a differentiator.

AkzoNobel - a sustainable innovation leader in industrial coatings

In an era where sustainability is no longer a differentiator but an industry expectation, AkzoNobel is setting new benchmarks for eco-conscious innovation in the wood coatings sector.

As a strategic partner to many of the world’s leading kitchen cabinet Original Equipment Manufacturer (OEMs), AkzoNobel is not only responding to evolving market demands but it is helping shape them also.

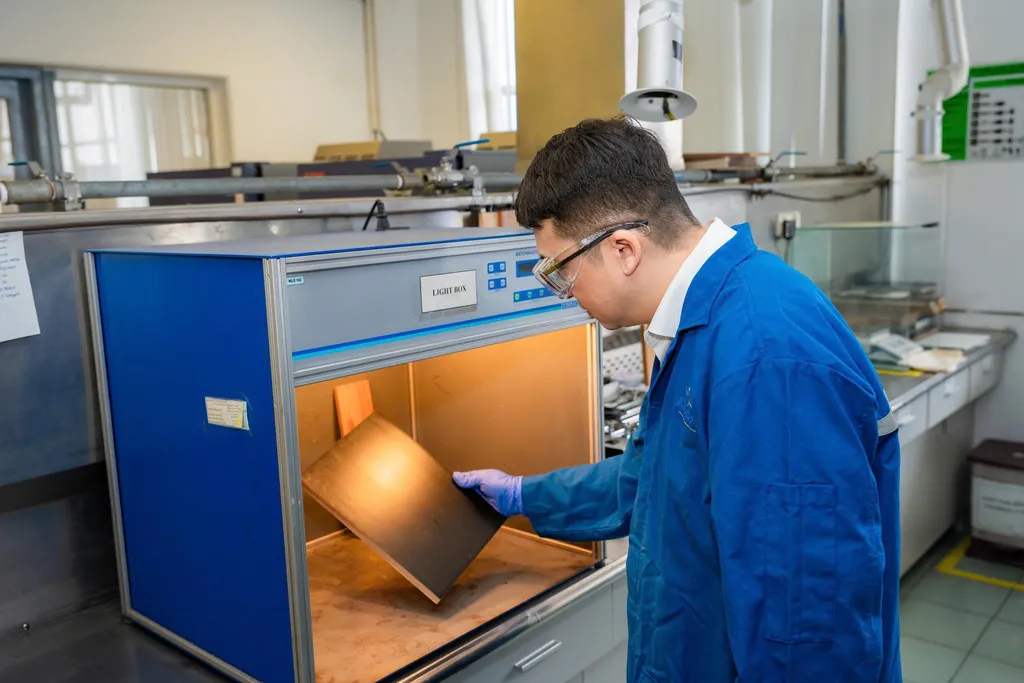

|

| Consistently maintains strict quality control to ensure international standards. |

A key technology for AkzoNobel is the UV-Curing with high-performance coatings, which is a game-changer for automated production lines, offering instantaneous curing with extremely low VOC emissions.

According to Leonard Leow, R&D Manager of Wood Finishes SEA at AkzoNobel, in Việt Nam, the company’s latest sustainability initiatives centre on the advancement of ultraviolet (UV)-cured coatings, which contain little to no VOCs.

“For kitchen cabinets, we apply UV coatings to the underside and complete the process with a UV topcoat, representing a significant step toward a lower carbon footprint solution,” said Leow.

By integrating seamlessly with LED curing systems, they dramatically reduce energy consumption and production time, key for high-volume, export-driven cabinet production.

Other key products are water-based solutions with low levels of volatile organic compounds (VOCs). Combining low-environmental impact with exceptional technical performance, AkzoNobel’s water-based PU coatings are designed to meet and exceed international durability standards. They offer robust scratch and chemical resistance, supporting long product life cycles while also reducing workplace exposure to harmful solvents.

These solutions align closely with green building certifications such as LEED and WELL, making them ideal for export products aimed at eco-conscious markets.

|

| AkzoNobel’s advanced coating technologies ensure global-quality finishes for export-oriented manufacturers. |

Leow added: “Our product range for the kitchen cabinet industry is designed to meet essential performance requirements, including stain and scratch resistance. In addition, we are actively promoting other more sustainable technologies, including bio-based solutions, as part of our ongoing commitment to reduce our value chain’s carbon footprint.

"Currently, our more sustainable coating solutions are primarily used by several esteemed customers within the furniture segment.”

According to Leow, at this stage, AkzoNobel’s coatings can contain up to 15 per cent bio-based material in production without reducing its performance, contributing to the principles of a circular economy.

“We are committed to advancing this further, with an ambitious goal of achieving 50 per cent bio-based content in close collaboration with our strategic customers and partners,” he said.

Denis Wang, Technical Manager Wood Finishes APAC, confirmed that sustainability is one of the core values of AkzoNobel.

He said: “It drives our company purpose, Paint the Future, and guides our long-term vision. We’ve set ambitious targets for 2030, including 50 per cent less carbon emissions in our operations and across our value chain (using 2018 as the baseline), 75 per cent of suppliers to meet sustainability expectations as assessed by EcoVadis in 2030 and 100 per cent circular use of materials in our own operations driven by reduce, reuse and recycle.”.

Furthermore, AkzoNobel is committed to becoming carbon neutral by 2050.

“Our mission also extends to helping customers lower their energy use and create high-quality products with minimal carbon footprints and emissions,” Wang added.