Society

Society

|

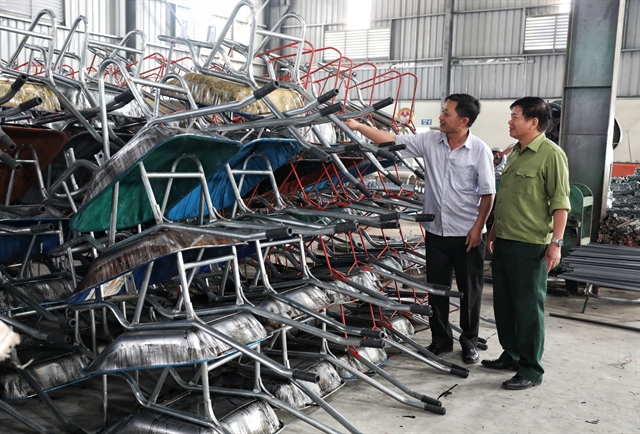

| Trần Văn Hùng (in white shirt) at his wheelbarrow factory. |

BẮC GIANG — Returning from the battlefield, Trần Văn Hùng, born in 1970, started a wheelbarrow-manufacturing business from scratch in his hometown in Tân Yên District, northern Bắc Giang Province, creating jobs for his fellow veterans and their relatives.

Hùng’s wheelbarrow-manufacturing factory, located in Ngọc Châu Commune, occupies a 2ha plot of land and is equipped with cutting-edge machinery.

Hùng stated that his company invested more than VNĐ200 billion to construct a new mechanical factory on 4.5 hectares last year to produce wheelbarrows and household products.

After serving for many years in the northernmost province of Hà Giang, he returned home in 1992 and faced many challenges.

He had to work several heavy jobs to make ends meet, yet he was still unable to escape poverty. As a result, he was always considering how to launch a business.

Veteran Hùng majored in welding at Technical Worker School No. 1, which is now the Hanoi University of Industry, in 1993. He applied for numerous jobs after graduating, but was turned down because of the order shortage amid the difficult economic situation facing the whole country at the time.

He went back to his hometown in search of a new strategy.

With the knowledge he had learned, Hùng borrowed money from friends and relatives to buy a welding machine. First, he fixed broken hoes and shovels and helped neighbours in welding useful tools.

Based on his observations of farmers' daily tasks and his acquired knowledge, Hùng created his first one-wheeled hand pushed vehicle for transportation.

After seeing how convenient the wheelbarrow was, he kept adding features, most notably improving the wheels, which allowed it to carry more cargo and roll more smoothly on any surface.

He started off just intending to build a wheelbarrow for his family, but when he saw how useful it was and how much people needed it, he started to produce more of his first wheelbarrow.

His wheelbarrows quickly ran out of stock. Hùng realised that he needed to grow the company and offer the wheelbarrows to more customers, both in the neighbourhood and in nearby provinces such as Bắc Ninh and Hải Dương.

A lot of mechanical shop owners refused to sell his wheelbarrows since the wheelbarrow takes up a lot of storage space in comparison to other commodities.

So, he sent two wheelbarrows to each business; one was for the shop owner to carry tools and small mechanical equipment, and the other was for sale.

Many consumers have come to rely on his wheelbarrow because of its versatility and ease of use.

He made the decision to invest in expanding production and launching mass production as the volume of orders rose. There were times in 2014–15 when his factory made hundreds of wheelbarrows in order to satisfy customer demand.

He intended to industrialise the mass manufacture of wheelbarrows after realising the market's enormous potential, but mechanical machinery demands a significant financial commitment.

Hùng drew up a roadmap to realise his plan gradually.

He upgraded the wheelbarrows at that time by purchasing mechanical machinery with all of the proceeds from the sales.

He founded Hùng Thảo Mechanical Limited Liability Company in 2017 with the help of loans provided by the local government.

With the capacity to create hundreds of thousands of wheelbarrows annually, the company has grown to become the largest and only wheelbarrow-making operation in Việt Nam.

An important turning point came in 2021 when an American company placed an order for wheelbarrows worth about $1 million, which allowed the company to go in a new direction.

Hùng, though, is never content with his achievements.

Learning about customers' needs and preferences in the US market, he designed new wheelbarrow models popular with American customers such as models with wooden handles, which are both light and sturdy.

He then began to learn more about some other overseas markets.

His factory can now manufacture every step and part of a wheelbarrow on its own.

He is also creative in taking advantage of, purchasing and reusing waste motorbike tyres to use as wheels for the wheelbarrows – an environmentally-friendly solution.

His company has exported wheelbarrows to big markets like the US and Australia with revenue of nearly $2 million per year.

Making contributions to homeland

|

| Hùng recycles waste motorbike tyres to use as wheels for the wheelbarrows. |

Hùng’s business has so far created jobs for 110 local workers, many of whom are veterans and their relatives, with wages averaging VNĐ8-12 million per month.

Chairman of the Bắc Giang Province Veterans Association Nguyễn Đức Thuận said veteran Hùng hails from a family with a revolutionary tradition, was trained and grew up in the army, and is an example of a veteran doing business. He is a typical model of a businessman who is compassionate and patriotic.

Every year his company donates hundreds of millions of đồng for people in difficult circumstances, policy beneficiary families and to help local families escape poverty.

His business also helps local authorities build welfare projects such as concrete roads and schools, helping Tân Yên District achieve the new rural style area title two years ahead of schedule.

His company also offers support worth VNĐ30 million to the Veterans Association at commune and district levels to remove dilapidated houses for three local families and provided wheelbarrow-manufacturing tools for poor, near-poor households and people living in difficult circumstances in the district.

Veteran Trần Văn Hùng is always an active and exemplary member in the association's movements such as: Veterans help each other reduce poverty and do good business; Veterans join hands to build new rural areas, and; The whole country joins hands for the poor - No one is left behind.

He was awarded many certificates of merit for his contributions to his community. — VNS