.jpg) Society

Society

.jpg)

|

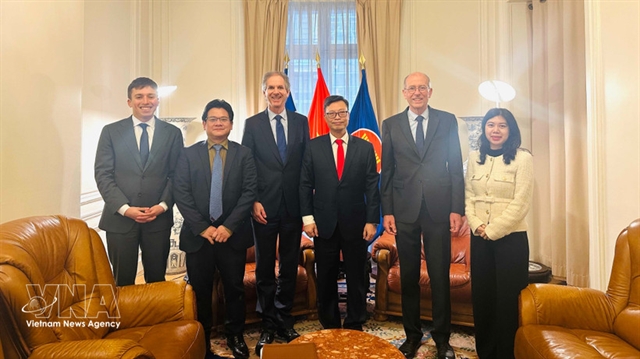

| Võ Nguyễn Thúy Hà, Phan Anh Quang and Lê Thị Thu Hà with their product which was produced from oyster shell and rice husk. — Photo from the students |

THỪA THIÊN-HUẾ — Using discarded agricultural and fishery waste, a group of high school students have successfully researched and manufactured unburnt lightweight materials from shells and rice husks.

With the project "Unburnt light ceramic materials from oyster shells and rice husks", a group of authors including Võ Nguyễn Thúy Hà, Phan Anh Quang and Lê Thị Thu Hà, who are students at Phú Bài High School in Hương Thủy Township of Thừa Thiên-Huế Province, won First Prize for high school students at the 5th National Student Start-up Festival.

Oyster shells and rice husk are waste products that are discarded after people exploit their original value, but the potential value of oyster shells and rice husk have not been fully utilised.

So the students used them again for a better purpose, turning waste into reusable products, turning things that were considered useless into useful things.

Võ Nguyễn Thúy Hà told phunuvietnam.vn: “Rice husk and oyster shells have long been utilised in many ways, but they have not yet been exploited to their full potential.”

“So we have sought to retain their best properties with the desire to turn these two by-products into non-toxic, environmentally-friendly green materials," said Hà.

With a desire to contribute to environmental protection, the students came up with the idea of creating an unburnt light ceramic material from rice husk and oyster shells that can replace traditional fired ceramics.

Phan Anh Quang said that the process of making traditional fired ceramics often creates dust, gases of carbon monoxide (CO), carbon dioxide (CO2) and sulphur dioxide (SO2), and solid waste such as ash, slag and burnt waste that cause environmental impact, depletion of land resources and scarcity of raw production materials.

Therefore, when combining oyster shells and rice husk, they will create new materials used in daily life such as art ceramics and wall panels for decoration, pots, jars and children's toys, Anh Quang said.

Unburnt ceramic products are waterproof and have flexural strength as compared to other ceramic products on the market, Anh Quang said.

Talking about raw materials to produce the products, the students said that, according to estimates of the Institute for Aquaculture Research I, the annual output of farmed oysters in Việt Nam is 30,000-35,000 tonnes. Thus, the amount of oyster shells discharged annually is equivalent to 25,500-29,700 tonnes.

If the team’s products are successfully brought to market, it will contribute to the treatment of a large amount of waste discharged into the environment every year and the maximisation of biological resources that have not been fully exploited to convert waste products into green, non-toxic materials.

Arduous journey

Despite their young age, their spirit and will are not small, and all three students have aspirations and desire to contribute a part of their efforts to help reduce waste from humans.

Research was a difficult process from the time the idea was conceived because the facilities at the school’s laboratory were insufficient.

In order to find the experimental machines, they had to ask for support from factories.

The students also had to work on both the project and their studies, so the workload became heavy, especially as this was the time of the high school graduation exam.

But with a strong will, energy and encouragement from the instructors, the group of authors achieved unexpected success.

Hà said: “During the implementation process, for many days, we slept and studied at the school's laboratory.”

“All three of us asked for permission from family and teachers to stay in the lab when the project was in the final stage to keep up with the progress,” Hà said.

“Although there were times of frustration because of many failures, the encouragement of teachers, parents and friends was the motivation for the team to try to complete the project well," she said.

The most difficult "problem" in the research was finding the right adhesive for the product.

Because in order to create a bond for the mixture of oyster shell and rice husk, when producing the finished product, the material must be light but not broken when subjected to strong impact and must be able to be used for a long time in erratic weather.

After researching documents and with support from instructors, the group members found that the combination of rice husk and calcium carbonate (CaCO3) from oyster shells would overcome the disadvantages of many types of other unburnt ceramic materials.

Oyster shells are high in calcium (96 per cent of crude CaCO3). The content of CaCO3 acts as an anti-caking agent, a carrier and a hardener to increase the shape of the product.

Hà said: “After purifying CaCO3 from oyster shells with NaOH 2% solution, drying, heating to remove CO2, oyster shells were ground into fine powder.”

“We mixed oyster shell powder with rice husk, pine glue, anti-fire additive (Antimony trioxide - Sb2O3) with a certain ratio, then brought this mixture into the mould for stamping,” Hà said.

“Next, when the product was dried in the sun, the mould was automatically separated, but for the best quality material, we continued to dry for about 29 days before getting the finished product," the student said.

After the product was successfully made and underwent durability testing under natural conditions, the group confidently brought the project “Unburnt light ceramic materials from oyster shell and rice husk” to the competition and received the award.

Their project received much attention from judges and a number of businesses.

The group decided to find an appropriate time to carry out the procedures for intellectual property rights registration and, in the future, they will find sponsors to produce the products.

Lê Thị Thu Hồng, a chemistry teacher in Phú Bài High School who is the instructor of the student group, said: “The students come up with the idea themselves.”

“During the testing process, there were many failures because the product did not meet quality criteria. However, they didn't give up and still worked hard to come to the end of their project,” Hồng said.

“Hopefully, the project will get sponsorship by businesses to produce products for selling," she added. — VNS

.jpg)