Opinion

Opinion

-transformed.jpeg)

|

| Dr Nguyễn Quân, Chairman of Việt Nam Automation Association and former Minister of Science and Technology. VNA/VNS Photo Minh Sơn |

Dr Nguyễn Quân, Chairman of Việt Nam Automation Association and former Minister of Science and Technology, spoke with the Vietnam News Agency about Việt Nam's enormous potentials in semiconductor development. However, he emphasised that if Việt Nam only focused on manufacturing and assembling, it would never establish a robust and complete semiconductor industry.

Việt Nam has been recognised for its rapidly evolving semiconductor ecosystem with abundant resources, a highly skilled workforce, and a wave of investment and collaboration in chip design engineering to the country. Could you tell us about the primary challenges Việt Nam is facing to develop the semiconductor industry?

The primary challenge in developing Việt Nam’s semiconductor sector is investment, as it is considered a high-tech, elite industry. After the design phase, extensive testing and experimentation labs are required, making chip design a costly endeavour. Currently, Việt Nam lacks these facilities and must resort to expensive overseas testing laboratories.

Furthermore, when it comes to production, chip manufacturing plants demand substantial investments. Additionally, we must invest in clean production lines, as chips require an exceptionally clean manufacturing environment. Advanced technologies such as robotics and automation also come at a high cost.

The second major challenge is our lack of self-reliance on input materials, especially in the electronic materials industry, particularly high-tech materials used in electronic component production. Currently, we are heavily dependent on imported materials. In the long term, we must work towards self-sufficiency in sourcing materials for chip production.

Việt Nam has two paths to develop the semiconductor industry: expanding manufacturing or enhancing capabilities and value in design and packaging. Which direction should we pursue?

Việt Nam should follow the path taken by successful countries and territories such as Taiwan (China), South Korea, and mainland China, which is to prioritise design as the most critical stage. If we only focus on manufacturing and assembling for other nations, we will never establish a comprehensive and thriving semiconductor industry.

Therefore, Việt Nam must take the route of becoming a leader in semiconductor design from the very beginning. Subsequently, we should focus on testing and large-scale production. Concurrently, we need to develop the electronic materials industry, ensuring a stable supply of materials for chip and semiconductor manufacturing.

In the future, we will witness cooperation in the field of technology and innovation between Việt Nam and the United States. As a former Minister of Science and Technology, how do you assess the opportunities for Việt Nam?

The cooperation programme in science and technology with the US has been in place for many years, dating back to the normalisation of relations between the two countries. We have also negotiated with the US on the Pacific Partnership Agreement.

Việt Nam signed agreements earlier with the US on cooperation in science and technology. Every year, we have exchanges between delegations of scientists from both nations.

The US has also established the Vietnam Education Foundation (VEF) to provide training for thousands of high-level science professionals in Việt Nam, many of whom have returned and made significant contributions to the country's science and technology.

With President Joe Biden's visit this month, I believe a new chapter in scientific and technological cooperation between the two countries has opened.

Among the four areas of cooperation that the US is focusing on with Việt Nam, the field of science and technology is of great interest. The US said it hoped that Việt Nam could become a strong nation in the electronics and semiconductor industry.

Việt Nam has great potential, not only in terms of a skilled workforce but also in its exposure to the electronics and semiconductor industry for 15 years. However, due to various factors, especially investment and technical support, we have not yet fully developed a genuine electronics and semiconductor industry.

I believe that with the support of the US in terms of resources and technology, we can develop the electronics and semiconductor industry. This is a high-value-added industry, as a semiconductor chip can be worth more than many tonnes of rice.

We can master high technology and enhance our economic efficiency. We can also become a significant player in cooperation with the US in the Southeast Asian region.

|

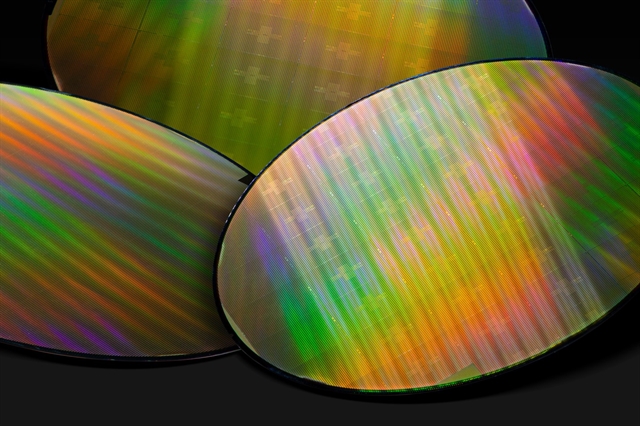

| Semiconductor wafers produced by FPT. Photo courtesy of FPT Software |

In the field of semiconductor chip design, Việt Nam currently has around 30 active companies with over 5,000 highly skilled engineers. If we look five years ahead, we will need 20,000 engineers, and in ten years, we will need up to 50,000 engineers. Do you think Việt Nam's human resources are genuinely in short supply, and does Việt Nam have the capability to train the workforce to keep pace with this emerging industry?

Việt Nam indeed has the potential for a high-tech workforce. However, the development of our human resources in any field depends on the needs of the economy and government directives.

One thing to note is that for many years, we haven't paid much attention to the electronics and semiconductor field. Consequently, university programmes in this area have not attracted many students.

Looking at the potential of our people, those in the fields of electronics and information technology, we are entirely capable of becoming experts in semiconductor and electronics design. If we currently have 5,000 engineers, I believe that number is acceptable. We've also learned that the enrollment targets for programmes related to electronics and semiconductors at universities have increased.

Vietnamese universities have a tradition of training in information technology and software, computer science, and hardware. If these human resources receive additional training in a short-term conversion programme, they can fully meet the requirements of the semiconductor and electronics industry.

I think training around 50,000 individuals to work in the semiconductor field is not an overly ambitious goal. Within the next ten years, I believe we can achieve that. The issue lies in how our products will be commercialised, to what scale they will serve the development needs of Việt Nam, or whether they will cater to the regional or global market.

This, again, depends on the market and can be determined by major electronics corporations, such as Samsung or Intel. They will decide how our semiconductor chips will be consumed.

If we collaborate effectively with large companies and major nations, we can undoubtedly develop the semiconductor industry to the extent we project. – VNS